Log in to view your upload history.

-3D PRINTING ; Please make sure min. Wall thickness>1.2mm, thinnest part≥0.8mm, hole size≥1.5mm. Insufficient in min. requirement will be auto-canceled

Supported file : STL / Obj.

Click here to upload or drag and drop your model to the canvas.

Click here to upload or drag and drop your model to the canvas.

The model is too large and has been resized to fit in the printer's build tray. [Hide]

The model is too large to fit in the printer's build tray. [Hide]

The model is too large, a fitting printer is selected. [Hide]

The model is too small and has been upscaled. [Hide]

Warning: The selected printer can not print in full color [Hide]

Warning: obj models with multiple meshes are not yet supported [Hide]

Warning: Unsupported DXF entity [Hide]

Warning: could not arrange models [Hide]

X:

×

Y:

×

Z:

cm

X:

×

Y:

×

Z:

cm

Bright is higher

Height (mm)

Model Stats:

| Material Volume: |

cm3

cm3 |

| Support Material Volume: |

cm3

cm3 |

| Box Volume: | cm3 |

| Surface Area: | cm2 |

| Model Weight: |

g

g |

| Model Dimensions: |

x x

cm

|

| Number of Polygons: | |

| Number of Shapes: | |

| Total Path: |

cm

cm |

| Print Time (hh:mm:ss): |

|

Incl. Support Charges:

Log in to view your upload history. Supported file format : STL / OBJ

Only upload ONE FILE CONTAIN ONE PART as if one file contains multiple part may cause error in printing.

LEAVE BLANK IF NOT REQUIRE.

What is FDM Infill? What is SLA Infill?

| COLOR | MATERIAL |

|---|---|

| BLACK | PLA , PLA PLUS , PLA PRO, PETG, ABS ,ABS PRO , ABS ANTI STATIC, TPU 95A, ASA , RESIN PLA , HIGH TEMP RESIN , HARD TOUGH, ABS RESIN , NYLON RESIN, BAMBU LAB PLA, BAMBU LAB PLA MATTE, BAMBU LAB ABS, BAMBULAB PETG PRO, BAMBU LAB PA12CF ( NYLON ), BAMBULAB POLYCARBONATE (PC). |

| WHITE | PLA, PLA PLUS, PLA PRO, PLA FDA GRADE, PLA LIGHT WEIGHT, ABS, ABS PRO, RESIN PLA, BAMBU LAB PLA, BAMBU LAB PLA MATTE, BAMBU LAB ABS |

| NATURAL | TPU, RESIN SLA, * BAMBU LAB POLYCARBONATE (PC)- 5% BLACK TINT |

| GREY | PLA PLUS, PLA PRO , ABS, ABS PRO, SLA RESIN, BAMBU LAB PLA, BAMBU LAB PLA MATTE, BAMBU LAB ABS, BAMBU LAB MULTI COLOR |

| YELLOW | PLA PLUS, PLA PRO, ABS, ABS PRO, TPU, BAMBU LAB PLA, BAMBU LAB PLA MATTE, BAMBU LAB ABS, BAMBU LAB MULTI COLOR |

| ORANGE | PLA PLUS, PLA PRO, ABS, ABS PRO, TPU 95A, BAMBU LAB PLA, BAMBU LAB PLA MATTE, BAMBU LAB ABS, BAMBU LAB MULTI-COLOR |

| RED | PLA PLUS, PLA PRO, ABS, ABS PRO, TPU 95A, BAMBU LAB PLA, BAMBU LAB PLA MATTE, BAMBU LAB ABS, BAMBU LAB MULTI-COLOR |

| PURPLE | PLA PLUS, PLA PRO, ABS PRO, BAMBU LAB PLA, BAMBU LAB PLA MATTE, BAMBU LAB MULTI-COLOR |

| BLUE | PLA PLUS, PLA PRO, ABS, ABS, ABS PRO, TPU95A, BAMBU LAB PLA, BAMBU LAB PLA MATTE, BAMBU LAB ABS, BAMBU LAB MULTI-COLOR |

| SILVER | PLA PLUS, PLA PRO, ABS PRO, BAMBU LAB MULTI-COLOR |

| GREEN | PLA PLUS, PLA PRO, ABS, ABS PRO, BAMBU LAB PLA, BAMBU LAB PLA MATTE, BAMBU LAB MULTI-COLOR |

| PINK | PLA PLUS, PLA PRO, ABS PRO, BAMBU LAB PLA, BAMBU LAB PLA MATTE, BAMBU LAB MULTI-COLOR |

| MATTE WHITE | PLA PRO, BAMBU LAB PLA MATTE, BAMBU LAB MULTI-COLOR |

| MATTE SERIES | |

| MATTE MEDIUM TORQUISE | PLA PRO, BAMBU LAB PLA MATTE, BAMBU LAB MULTI-COLOR |

| MATTE CREAM YELLOW | PLA PRO, BAMBU LAB PLA MATTE, BAMBU LAB MULTI-COLOR |

| MATTE TANGERINE | PLA PRO, BAMBU LAB PLA MATTE, BAMBU LAB MULTI-COLOR |

| MATTE BLACK | PLA PRO, BAMBU LAB PLA MATTE, BAMBU LAB MULTI-COLOR |

| MATTE CORAL RED | PLA PRO, BAMBU LAB PLA MATTE, BAMBU LAB MULTI-COLOR |

| MATTE LAVENDER | PLA PRO, BAMBU LAB PLA MATTE, BAMBU LAB MULTI-COLOR |

| MATTE MINT GREEN | PLA PRO, BAMBU LAB PLA MATTE, BAMBU LAB MULTI-COLOR |

| MATTE LIGHT YELLOW | PLA PRO, BAMBU LAB PLA MATTE, BAMBU LAB MULTI-COLOR |

| MATTE PINK | PLA PRO, BAMBU LAB PLA MATTE, BAMBU LAB MULTI-COLOR |

| MATTE LIGHT BLUE | PLA PRO, BAMBU LAB PLA MATTE, BAMBU LAB MULTI-COLOR |

| MATTE GREY | PLA PRO, BAMBU LAB PLA MATTE, BAMBU LAB MULTI-COLOR |

| MATTE GREEN | PLA PRO, BAMBU LAB PLA MATTE, BAMBU LAB MULTI-COLOR |

| SILK SERIES | |

| SILK RED | PLA PRO, BAMBU LAB MULTI-COLOR |

| SILK GREEN | PLA PRO, BAMBU LAB MULTI-COLOR |

| SILK DARK ROSE GOLD | PLA PRO, BAMBU LAB MULTI-COLOR |

| SILK ANTIQUE GOLD | PLA PRO, BAMBU LAB MULTI-COLOR |

| SILK DARK RAINBOW | PLA PRO, BAMBU LAB MULTI-COLOR |

| SILK RAINBOW | PLA PRO, BAMBU LAB MULTI-COLOR |

| SILK SILVER | PLA PRO, BAMBU LAB MULTI-COLOR |

| SILK BLACK | PLA PRO, BAMBU LAB MULTI-COLOR |

| SILK LIGHT YELLOW | PLA PRO, BAMBU LAB MULTI-COLOR |

| SILK RED COPPER | PLA PRO, BAMBU LAB MULTI-COLOR |

| SILK LIGHT PURPLE | PLA PRO, BAMBU LAB MULTI-COLOR |

| SILK CHAMPANGE | PLA PRO, BAMBU LAB MULTI-COLOR |

| SILK BLUE | PLA PRO, BAMBU LAB MULTI-COLOR |

| SILK PINK | PLA PRO, BAMBU LAB MULTI-COLOR |

| SILK GOLD | PLA PRO, BAMBU LAB MULTI-COLOR |

| SILK BRONZE GREEN | PLA PRO, BAMBU LAB MULTI-COLOR |

| SILK TEAL BLUE | PLA PRO, BAMBU LAB MULTI-COLOR |

| SILK JADE GREEN | PLA PRO, BAMBU LAB MULTI-COLOR |

| SILK DEEP CYAN BLUE | PLA PRO, BAMBU LAB MULTI-COLOR |

| SILK WHITE | PLA PRO, BAMBU LAB MULTI-COLOR |

| SILK PURPLE | PLA PRO, BAMBU LAB MULTI-COLOR |

| GALAXY SERIES | |

| GALAXY RED | PLA PRO, BAMBU LAB MULTI-COLOR |

| GALAXY PURPLE | PLA PRO, BAMBU LAB MULTI-COLOR |

| GALAXY BLUE | PLA PRO, BAMBU LAB MULTI-COLOR |

| GALAXY BLACK | PLA PRO, BAMBU LAB MULTI-COLOR |

| GALAXY GOLD | PLA PRO, BAMBU LAB MULTI-COLOR |

| LUMINOUS SERIES | |

| LUMINOUS SKY BLUE | PLA PRO, BAMBU LAB MULTI-COLOR |

| LUMINOUS GREEN | PLA PRO, BAMBU LAB MULTI-COLOR |

| LUMINOUS PURPLE | PLA PRO, BAMBU LAB MULTI-COLOR |

| TRANSPARENT SERIES | |

| TRANSPARENT RED | PLA PRO, BAMBU LAB MULTI-COLOR |

| TRANSPARENT GREEN | PLA PRO, BAMBU LAB MULTI-COLOR |

| TRANSPARENT YELLOW | PLA PRO, BAMBU LAB MULTI-COLOR |

| TRANSPARENT PURPLE | PLA PRO, BAMBU LAB MULTI-COLOR |

Infill in 3D Printing: Definition

By Team Xometry

Credit : Xometry.com

3D printing infill refers to the internal structure of a 3D printed part. This internal structure can be produced using many different shapes. The purpose of infill is to optimize part weight, strength, and printing time. Many different infill patterns exist. These standard designs can be selected in the 3D slicing software menu used to prepare parts for printing.

This article will define 3D printing infill, discuss how to select the correct infill pattern and density.

What Is Infill in 3D Printing?

“Infill” in 3D printing refers to the internal patterns found inside most 3D printed parts. Parts made by some manufacturing processes, like injection molding, must be made either completely solid or completely hollow. 3D printed parts, on the other hand, can be made with a variety of structural patterns that partially fill the space inside the outer printed walls. Almost all 3D printing technologies require infill. This is the case because printing objects in a solid material are too costly and time-consuming.

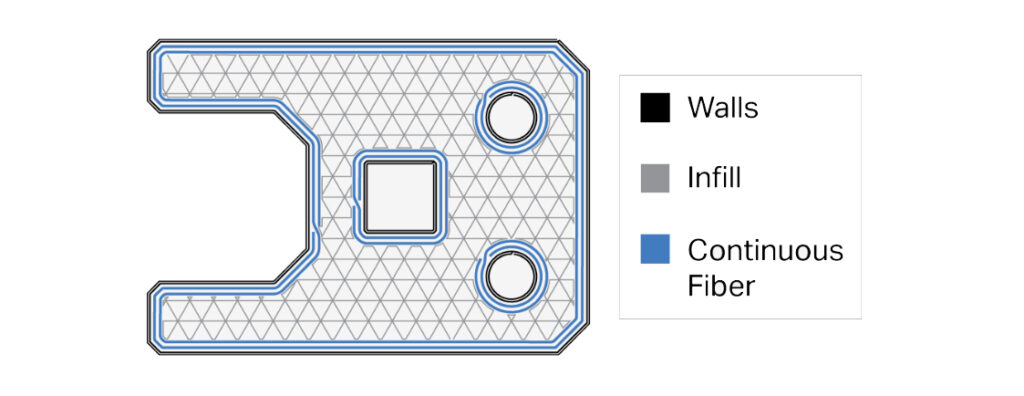

Figure 1 below shows the infill of a 3D printed part.

What Is the Purpose of Infill in 3D Printing?

The purpose of Infill in 3D printing is to save both printing time and material by creating a lattice structure inside of a 3D printed part. Printing fully dense parts is often unnecessary and is just a waste of material. The infill can be strategically placed to provide strength where in-service loads on the part are the highest. The greater the percentage of infill, the higher the density of the part.

What Are the Main Parts of Infill in 3D Printing?

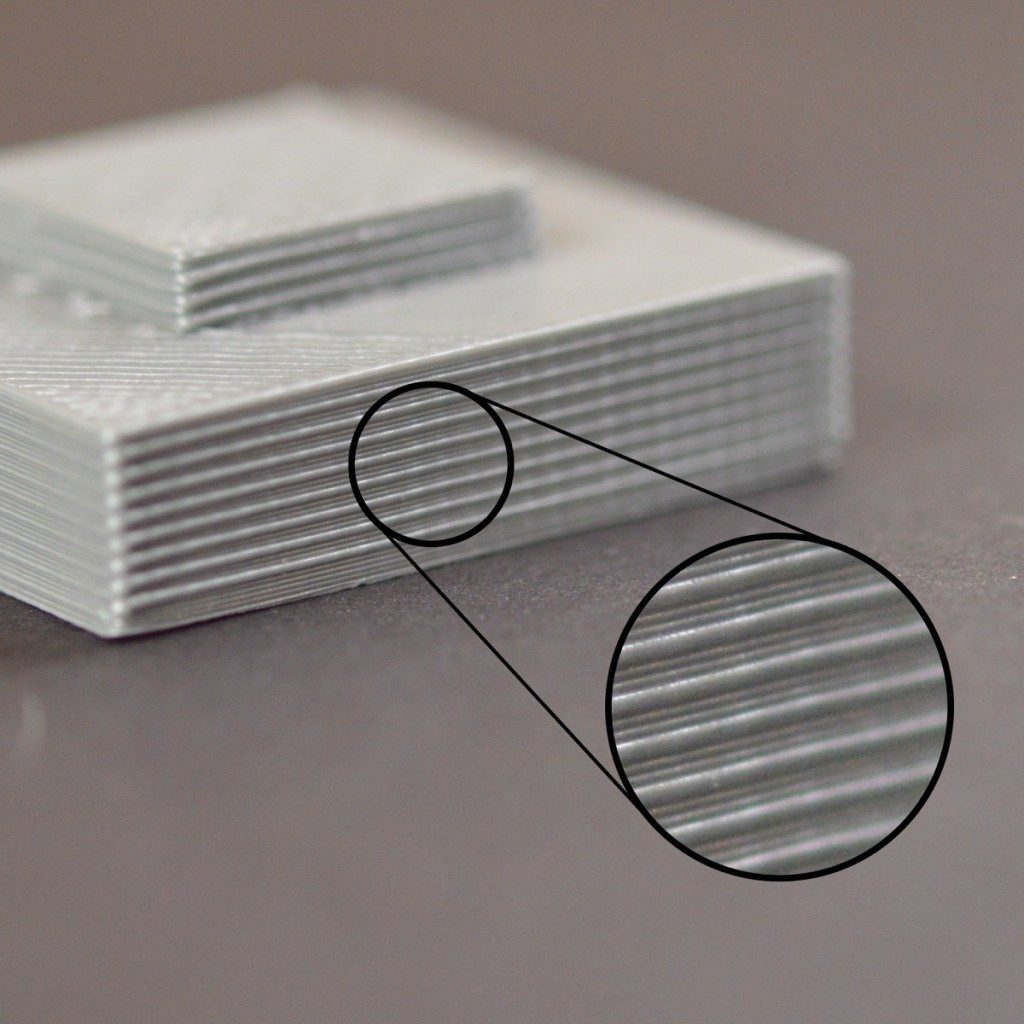

A typical 3D printed part will have an outer shell with a predefined thickness. The infill structure is completely enclosed by this outer shell and is not visible when the part print is complete. The infill will be evenly distributed throughout the part. 3D printing infill is normally printed at higher speeds than the outer shell to save time. The infill print lattice is also not as thick as the shell.

Cubic Is The Types of Infill In Our Standard 3D Print

The cubic infill type creates cubic volumes inside the part. It does this by producing a layered pattern similar to a triangular infill. However, it offsets each subsequent layer to build enclosed cube-shaped volumes in the part. The cubic volumes are oriented with the cube balanced on one corner.

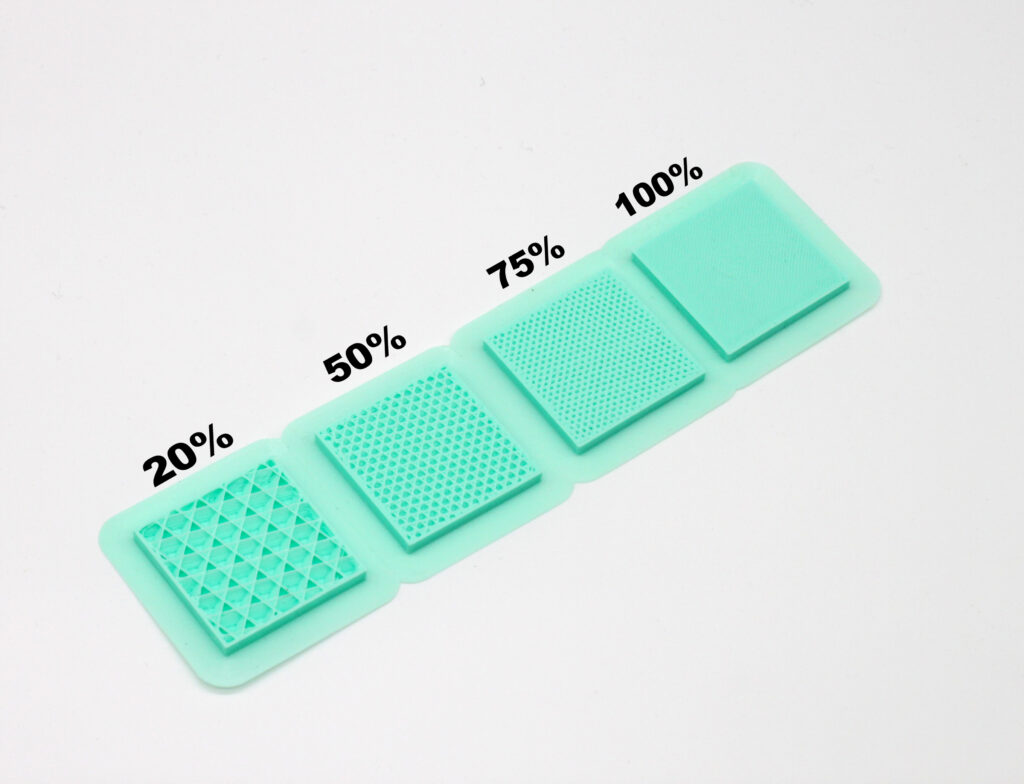

What Does the Ideal Value of the Infill Percentage Depend Upon?

The main determining factor for infill percentage is the type of application for which the part is destined to be used. Prototypes and hobbyist creations rarely need more than 20% infill. Functional parts that will be exposed to mechanical stress loads will typically require infill percentages of 50% or more.

What Is the Recommended Infill Percentage for Other Simple Exposure Objects?

For objects that will not see any significant mechanical load, a fill percentage of 20% is sufficient. It must be noted that the geometry of the part may require a different infill percentage. For example, a flat, horizontal surface may need a denser infill percentage to ensure that the top layer does not sag due to a lack of support.

How Much Infill Is Required To Achieve Maximum Tensile Strength?

The higher the infill percentage, the higher the tensile strength of the part. It must be noted that infill percentage is not the only factor that determines tensile strength. For example, filament material and print orientation play a major role. FDM parts, in particular, are anisotropic. They are weaker along the z-axis due to interlayer bonding weakness. If an FDM part is loaded in the z-direction, the dominant factor controlling its tensile strength will be the interlayer bonding quality. Infill percentage will have little effect in this case.

What Is a Good Infill Density?

In most cases, an infill density between 20 and 50% is ideal. Less than 20% results in flimsy parts whereas more than 50% begin to take too much printing time and use too much material.