We welcome you to the 3DMSR website, 3DMSR.COM (the “3DMSR WEBSITE” or “Website”).

The Website is managed by 3DMASTER STUDIO SDN. BHD., (collectively, “3DMSR”, “we”, “us” or “our”) a company incorporated in Malaysia

and having its business address at F01-03, Jalan PBS 14/2, Taman Perindustrian Bukit Serdang, Seri Kembangan 43300 Selangor, Malaysia

Your access to and use of the Website and the Services are subject to the following terms and conditions

("Terms and Conditions").

Your Consent

Please take a few minutes to read our Terms and Conditions. By using the 3DMSR website

and service, you acknowledge to have read, understood and agree to be bound by these Terms and

Conditions and to comply with all applicable laws and regulations. If you do not agree with these Terms

and Conditions, you should not use the 3DMSR Services and Website.

Modifications

We reserve the right to update or modify these Terms and Conditions at any time, without prior notice, by

posting any such revised version of these Terms and Conditions behind the link marked "Terms and

Conditions of Use" at the bottom of each page of this Website. Your continued use of the Website after

we have posted the revised Terms and Conditions constitutes your agreement to be bound by the revised

Terms and Conditions.

3DMSR Services 3DMSR Services are provided through the website and over email (3dmaster.hr@gmail.com).

Through the website you can obtain information about our services, request a quotation, place orders for

products and receive such other services as we may offer from time to time (collectively the “Services”).

3DMSR uses AMFG software for its automatic uploading system that will check and price 3D

models.

Manufacturing Services

Our manufacturing service is used to create physical 3D models from digital 3D designs.

The 3D design (or ‘3D file’ or ‘3D model’) can be uploaded to our website, viewed in 3D, checked for

manufacturability, quoted for manufacture in a range of materials and ordered from us to be

manufactured. Information and technical data sheets for the materials and manufacturing technologies

can be found on the materials and technology pages on our website.

Unless stated differently during the checkout process, all costs will be billed and collected by 3DMSR

. If your model is not manufacturable or has features that may lead to unsatisfactory results of the

manufacture process, we will contact you and advise the changes that need to be made. If changes are

not possible, a refund can be given providing that manufacturing has not commenced. We use software

provided by AMFG (Autonomous Manufacturing Ltd) that checks your model for manufacturability (‘health

check’) and possibly repairs it automatically. Models that do not pass the health check for 3D printing will

require an inspection by one of our expert 3D designers. We might – but not necessarily will – be able to

fix your model or make modifications that will allow it to be manufactured. Most 3D files require simple

fixing that can be completed in under 10 minutes, this is provided FREE OF CHARGE by manufacture process,

we will contact you and advise the changes that need to be made. If changes are

not possible, a refund can be given providing that manufacturing has not commenced. We use software

provided by AMFG (Autonomous Manufacturing Ltd) that checks your model for manufacturability (‘health

check’) and possibly repairs it automatically. Models that do not pass the health check for 3D printing will

require an inspection by one of our expert 3D designers. We might – but not necessarily will – be able to

fix your model or make modifications that will allow it to be manufactured. Most 3D files require simple

fixing that can be completed in under 10 minutes, this is provided FREE OF CHARGE by manufacture process,

we will contact you and advise the changes that need to be made. If changes are

not possible, a refund can be given providing that manufacturing has not commenced. We use software

provided by AMFG (Autonomous Manufacturing Ltd) that checks your model for manufacturability (‘health

check’) and possibly repairs it automatically. Models that do not pass the health check for 3D printing will

require an inspection by one of our expert 3D designers. We might – but not necessarily will – be able to

fix your model or make modifications that will allow it to be manufactured. Most 3D files require simple

fixing that can be completed in under 10 minutes, this is provided FREE OF CHARGE by 3DMSR. Models t

hat require fixing in excess of 10 minutes may require expert services for file fixing. 3DMSR

only offer file fixing services in combination with an order of 3D prints of the model. By purchasing

file fixing services you will reduce, but not completely remove, the risks related to the potential

non/limited-manufacturability of your model and the limits of the 3D printing technology, which might lead

to unsatisfactory results of the 3D-print process.

A model that successfully passes our checks for manufacturability, either before or after having been

automatically repaired, might still be non-manufacturable. We run routine checks on all models and will

advise you, but we shall not be held responsible for any loss, damage or costs incurred if the model has

features that are outside the guidelines stated on our design guide page on the 3DMSR website.

CAD Design Services

Our CAD Design Service is used to create high quality 3D files optimized for 3D printing.

Account Terms

You must be at least eighteen (18) years of age to use this Service. If you are under 18, you may use 3DMSR

only with involvement of a parent or guardian. You must provide current, accurate

identification, contact, and other information that may be required as part of the registration process

and/or continued use of the Service. You are responsible for maintaining the confidentiality of your

Service password and account, and are responsible for all activities that occur there under. We will not be

liable for any loss or damage from your failure to maintain the security of your account and password. We

reserve the right to refuse service to or terminate service of anyone at any time without notice for any

reason.

Manufacturing Service Processes

01 Get an Instant Quote / Email Quote/WhatsApp Quote

To order a 3D print of a 3D model or recieve a quote, you must have a 3D file. Whilst we accept many

different 3D file formats the file extension .stl is preferable. If you have multiple parts, please export each

part as an individual STL file, multipart STL files will cost more. You start by uploading the 3D file(s) to the

instant quote tool on our website or send us the file(s) via email, either as an attachment or through the

contact form on our website.

Using the instant quote tool, you can select manufacturing specifications for each part you wish to order.

These include the quantity, material, finish and the turnaround time. There may also be additional

services you can select from. If you have emailed the file to us we may ask for more information about the

parts before selecting the manufacturing specifications for you. After all of your parts have manufacturing

specifications, we ask that you to provide us with information we need for the delivery of the model.

Please be informed that the language to be used during the whole ordering process is English. Quotes

are valid for 30 days from the date of issue.

02 Unacceptable orders, cancellation of orders by us

There may be technical or other reasons why we cannot accept or must cancel your order during the

entire ordering process, even after our acceptance of your order. (Such reasons can be for example but

not limited to the infeasibility of the model, the features of your model, the destination of the delivery you

indicated in your order etc.) In case we cancel your order 3DMSR will contact you via email/WhatsApp.

Any functioning weapon or parts from weapons will not be printed. Any parts for weapons concealed or

disguised as other parts in an attempt to bypass this rule will remain the responsibility of the person(s)

who upload the files and they will be held liable for any legal actions as a result of the printing. Any parts

deemed to be of an extreme offensive nature will not be printed.

03 Prices

The prices displayed are based on pricing scheme of the Turnaround time you choose and are valid only

for the moment that they are displayed. 3DMSR reserves the right to change its prices without

prior notice. Such changes however will have no effect on orders completed before the posting of a new

price. We do our best to prevent errors in the pricing. However, should an error occur, we are not bound

by our offer and may cancel the order.

04 Payment and price

Payment must be made in full prior to printing unless an order is confirmed via email as bulk in which

case 50% payment can be made upfront and 50% upon completion. Payment must be made in full prior

to delivery. Lead times for the printing process start on completion of payment and not from the time of

the upload. The cut-off for Express orders is payment made before 2pm on weekdays. The lead time for

Orders paid after 2pm will start from the next working day. Payment should be made through an invoice

emailed out and should be paid by credit card or bank transfer. If agreed on payment after delivery the

payment will have to be made within 30 days of the Invoice or Delivery date. If a payment is late an 8%

plus the Bank Negara base rate fee will be added for business to business transactions.

05 Acceptance

After sending your order, we will send you an order confirmation to the email address with which you

signed-in or supplied with the upload. The order confirmation will be effective as of the date on which the

order confirmation is sent to you. If we cannot accept your order, we will contact you by email. You should

verify the details in the confirmation email. If there are errors you should contact us as soon as possible

by sending an email to our customer service.

06 Amendments to Order including Adding files/Changing files

After the acceptance and payment of the order, there can be no changes to the files or processes,

excluding the addition or removal of Print Finishing. If the file has not already been printed, any changes

are subject to a MYR50.00 admin charge which must be paid for before the change comes into effect.

07 Lead Times

Lead times are only estimates and NOT IN ANY WAY guaranteed. Infrequent and unpredictable factors

like machine failure, power cuts and acts of God may cause orders to be delayed by a number of days. If

Express orders take significantly longer than expected, a partial refund may be given to equal the cost of

an Economy order, but no full refunds are given. There are no Lead time related refunds for Economy

orders. If you are on a deadline, it is strongly advised that you choose the Express tariff.

08 Shipping

Your order will be delivered to your shipping address or will be available for pick-up depending on the

service you choose. We are not liable for incorrect shipping addresses, and no refunds are given if

incorrect shipping addresses are given. All packages are sent out in a protected box and by recorded

delivery. In the event that packages are returned to us we will resend them out, though this may incur

additional charges. In case of doubt, check the delivery address on any of the update notification emails

you have been sent. We are not liable for any damage or cost caused by delay in shipping or delivery.

Change of shipping address is permitted, however your model will be placed at the back of the queue for

printing and lead times will commence from the date of the address change unless otherwise stated.

09 Cancellation of your order, return of models

Due to the nature of our Services, you cannot cancel your order after it goes into production. Orders that

contain non-refundable items are still cancellable, however note that refund or cancellation will not apply

to items in the order that are non-refundable. We are not responsible for your design should it not work or

not fit the designed purpose unless what we provide is substantially dimensionally different to what has

been supplied to us in STL format.

10 Minimum Guaranteed Thickness

Parts are guaranteed to a minimum wall thickness of 1 mm. We will print things thinner than 1 mm, but it

is at your own risk. If these break in our hands, your hands, during delivery, or lost during the cleaning

process, it will not be covered or re printed for free. Although, we do our best to check over every single

model for printing, sometimes thinner parts can be missed, 3DMSR is not held responsible if

the parts are missed and printed anyway which results in a failed or broken part.

11 Support Removal, Polishing and Painting

Support of 3d printed part is not removed by default. Additional charges will be charge if using this service (if available).

Polishing and painting are additional processes to the manufacturing time, price and lead times that are stated.

If you agree to using one of these services then you accept that an additional 3 working days with additional charges,

per service may be added to the lead time and price if necessary. Clients shall expect that support removal, sanding or surface repair will not be as smooth

and sharp as to be expected from injection moulding. Some unreachable area by machine will not be able to perform this additional service. We disclaim

any liability for any cracks or damages that may occur to 3D printed parts during the support removal process.

12 Use of 3rd Party Companies

In certain circumstances it may be necessary for 3DMSR to use a 3rd party company to

complete orders or certain aspects of a job. e.g. finishing work. 3DMSR can not be held

responsible if there are any problems or longer lead times caused by using this 3rd party. Although we

strive to complete jobs within the lead times stated, we cannot always guarantee these.

13 Refund of Production Run Sample

If you are looking to place a production run with us but need a sample first, we are able to offer a refund

of the sample order, up to the value of MYR40.00 excluding postage, once an order with a value of MYR500.00

and postage is placed with us for the same part, a refund can be issued. Only 1 sample refund is allowed

per order, maximum refund amount is MYR40.00.

14 Delays to Order

In some very rare circumstances there may be a delay to your order, in these circumstances there may

be a variety of reasons which include, but are not limited to; failure of Quality Control due to discolouration

or damage, machine failure, power cuts and ‘Acts of God’. If one or more of these issues do arise, we will

re-print the affected files, but this may cause a delay to the order while we await the reprints. As these

problems are always unforeseen, 3DMSR accepts no responsibility for missed deadlines and is

under no obligation to offer a refund or any form of compensation.

15 Warranty

As 3DMSR is independent from the design of the part, 3DMSR offers NO warranty

on any parts and does not insure against design in any way.

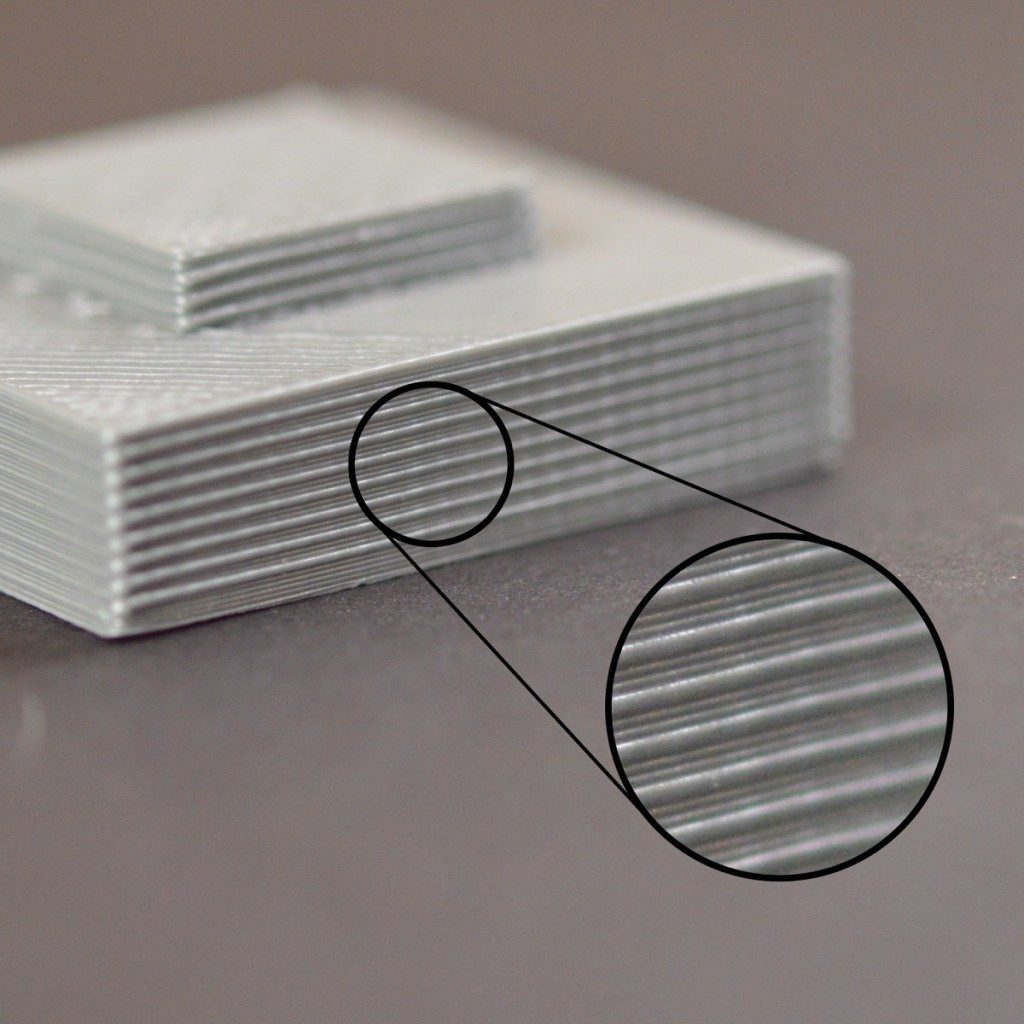

Though 3D printing is an excellent and cost effective way to manufacture low volume and one off items,

the quality and price are unlikely to match those of mass produced items. Misunderstanding of strength,

surface finish and cost are not grounds for a refund in any case.

3DMSR MAKES NO WARRANTY OTHER THAN THOSE MADE EXPRESSLY IN THIS

TERMS AND CONDITIONS TO THE FULLEST EXTENT PERMITTED BY LAW, 3DMSR

HEREBY EXPRESSLY DISCLAIMS ANY REPRESENTATIONS OR WARRANTIES OF ANY KIND,

EXPRESSED OR IMPLIED, INCLUDING WITHOUT LIMITATION WARRANTIES OF

MERCHANTABILITY, FITNESS FOR ANY PARTICULAR PURPOSE, OR NON-INFRINGEMENT. SOME

STATES OR COUNTRIES DO NOT ALLOW LIMITATIONS ON IMPLIED WARRANTIES, SO THE

FOREGOING LIMITATIONS MAY NOT APPLY TO YOU.

CAD Design Service Processes

01 Client’s obligations

The Client will provide or assist us in obtaining whatever materials, text or information are required for the

provision of the services. We reserve the right to charge for time spent acquiring or amending such

materials, text or information where those supplied by the Client are inadequate, or where the Client’s

instructions are inaccurate or incomplete.

The Client will review all specifications, drafts and proofs provided by us and provide feedback and/or

approval in a timely manner.

The Client will thoroughly check such specifications, drafts and proofs provided by us before signing off

on them. Once written approval has been given the Client will have no further opportunity to make

changes to the final product and we shall not be responsible for any error subsequently discovered in the

final product. Nor will we be liable for any Client dissatisfaction with the product where the final product is

produced in accordance with the signed-off specification. Any changes we do subsequently agree to

make will be at our sole discretion and we reserve the right to charge for them. Any claims for damage or

short supplied goods must be made in writing within seven days of goods being received.

Information sent from the client about specification, modification or general product information must be

sent via email and not in hand written or verbal form. Errors occurring from information in non email from

will not be covered for refundable or free of charge amendments to both digital or physical works.

02 Intellectual property

The Client represents and warrants to 3DMSR that any elements of text, graphics, images,

designs, trademarks or other material supplied or disclosed to 3DMSR are the property of the

Client or the Client has permission from the rightful owner to use each of those elements and that 3DMSR

its use of such material shall not infringe the intellectual property rights of any third party.

3DMSR will inform the relevant governing bodies in the event that it finds itself in possession of

an illegal image. Any product produced by 3DMSR for the Client using or containing anything

supplied or disclosed by the Client which infringes the intellectual property rights of any third party will

remain the liability of the Client and the Client will indemnify and keep indemnified 3DMSR

against any loss, damage claim or expense arising out of such infringement.

Where all sums owed to us under this agreement have been received, 3DMSR will assign to

the Client all intellectual property rights (including copyright) in the final product as are owned by us and

capable of assignment. All images, text, layouts, website scripts and source code appearing on or

associated with our websites are copyright of 3DMSR. All media published on our websites

remain the intellectual property of 3DMSR, 3DMSR shall have the right to use the

Client’s name & logo royalty-free in its own marketing material.

03 Retention of title

All goods or services sold or supplied by 3DMSR remain our property until payment is made in

full. Though the intellectual property of files is under ownership of the client, data files and drawings

produced will remain property of 3DMSR until a release fee is agreed. This fee is at our

discretion, though our standard release fee is twice that of the cost of the CAD work and is an additional

cost to that of the CAD work itself.

04 Functionality of digital designs created by 3DMSR

All designs will be to the best of our knowledge and ability, however with prototyping, this may take a few

attempts to produce an item fit for purpose. After agreed client sign off of digital items 3DMSR

bears no responsibility for the fit, form and functionality of the parts produced. Amendments and future

prints are subject to standard our chargeable rates.

05 Warranties and liabilities 3DMSR warrants that to the best of its knowledge and belief the final product shall not infringe

any third-party rights or be in any way contrary to Malaysian law. All other warranties or representations

whether express, implied or statutory, with respect to our service, including, without limitation, any implied

warranties of merchantability, accuracy, fitness for a particular purpose, or non-infringement are hereby

excluded to the maximum extent permitted by law. No oral or written information or advice given by us

shall create a warranty. 3DMSR aggregate liability to the Client under this agreement

shall in no circumstances exceed an amount equal to the total amount actually paid by the Client under

this agreement. In no event shall 3DMSR be liable to the Client for any loss of business, loss of

opportunity, profits or goodwill or for any other indirect or consequential loss or damage whatsoever. This

shall apply even where such a loss was reasonably foreseeable or we had been made aware of the

possibility of the Client incurring such a loss. The Client shall indemnify and keep indemnifying 3DMSR

from and against any and all damage, loss, costs, expenses (including legal costs and expenses)

and liability whether civil or criminal which we may incur or suffer resulting from any act, neglect or default

of the Client or its agents, employees or licensees, or the infringement of the intellectual property rights of

any third party.

06 Confidential information

The parties agree to treat as secret and confidential and not at any time for any reason during or after the

termination of the agreement to disclose or permit to be disclosed or made use of any confidential

information concerning the other’s business which they may acquire in the course of the agreement.

The above restrictions shall not prevent: (a) the disclosure of information if required by law; or (b) the

disclosure of information which is already in the public domain otherwise than through unauthorised

disclosure by the Consultancy.

07 General

Amendment: Any valid alteration to or variation of this agreement must be in writing and signed on behalf

of each of the parties by a duly authorised representative.

No Waiver: No failure of either party to enforce at any time or for any period any term or condition of the

agreement shall constitute a waiver of such term or of that party’s right later to enforce all terms and

conditions of the agreement.

Severance: If any provision of the agreement is declared by any judicial or other competent authority to

be illegal, void, voidable or otherwise unenforceable, or indication of the same is received by either of the

parties from any relevant competent authority, such provision shall be deemed severed from the

agreement and the remaining terms of the agreement shall remain in full force and effect.

Force Majeure: Neither party shall be liable for any delay in performing or failure to perform its obligations

under the agreement to the extent that and for so long as the delay or failure results from any cause or

circumstance whatsoever beyond its reasonable control (an “event of force majeure”) provided that the

event of force majeure is not due to the fault or negligence of that party. Each party shall use its

reasonable endeavours to minimise the effects of any event of force majeure. The Client’s obligation to

pay all amounts due under this agreement is explicitly excluded from the provisions of this clause.

Jurisdiction: The agreement is governed by and is to be construed in accordance with the laws of Malaysian

and shall be subject to the exclusive jurisdiction of the Courts of Malaysia.

Use of the 3DMSR Website

Copyright and all other proprietary rights in the content of the Website (including but not limited to

software, audio, video, text and photographs and excluding all User Generated Content) rests with 3DMSR

or its licensors. All rights in the content not expressly granted herein are reserved. Except

as otherwise provided, the content published on this Website may be reproduced or distributed in

unmodified form for personal, non-commercial use only. Any other use of the content, including without

limitation distribution, reproduction, modification, display or transmission without the prior written consent

of 3DMSR strictly prohibited. You also agree that you will not use any robot, spider, other

automated device, or manual process to monitor or copy any content from the Service. Our rights include

rights to (i) the Service developed and provided by us; and (ii) all software associated with the Service. All

copyright and other proprietary notices shall be retained on all reproductions.

This Website may provide links to other websites that are not under the control of 3DMSR. 3DMSR

shall not be responsible in any way for the content of such other websites. 3DMSR

provides such links only as a convenience to you, and the inclusion of any link to any such

websites does not imply endorsement by 3DMSR of the content of such websites.

Since the 3DMSR Service is a web based service, it might be subject to temporary downtime.

From time to time we also update our Website, which will result in the Website not being available for a

certain period of time. We will endeavour to ensure that the Website operates reliably and consistently,

but we do not warrant that the Website will operate uninterrupted without any faults. We are not

responsible for any losses suffered by you as a result of any interruption of the Website, suspension of

your access to the Website.

User Generated Content

The term “User Generated Content” when used in this Terms and Conditions shall mean any content

uploaded to the Website by you, including but not limited to all uploaded 3D designs, pictures of your 3D

objects, pictures of any model, comments on the Website, specifications provided in your order as well as

the printed model we create for you based on your User Generated Content. All User Generated Content

should not be or contain abusive, harassing, threatening, defamatory, obscene, fraudulent, deceptive,

misleading, offensive, pornographic, illegal or unlawful information or be likely to infringe or infringing on

any intellectual property rights. Intellectual property rights means copyright, patent, registered design,

design right, trademark, trade secret or any other proprietary or industrial right.

3DMSR has no obligation to review the User Generated Content and can in no way be held

responsible for the content of the User Generated Content.

ALL data created/supplied by you remains your own intellectual property, unless you grant us your

permission to distribute and share images and information of your parts, this does not include distributing

the 3D file(s) that you have supplied us with. By paying for your order you agree that if necessary we are

able to outsource your 3D data to one of our carefully selected partners, who they themselves are

covered under ours and their own non-disclosure agreements that they won’t be able to use any of your

data without first seeking you permission.

By agreeing to our service ‘Social Postage’* you agree that 3DMSR is allowed to show and

distribute images of your files, but not including the 3D data itself, via any of our channels, this includes

our website and social media channels but it is not limited to these methods. By agreeing to this service

we do not need to seek your written permission to distribute images of your files through any of our

channels and you are not able to request for pictures to be removed after something has gone live.

*(The Social Postage button this means that if 3DMSR decide to use any images of your parts

through any of means, you will have your postage costs refunded back to you, this is at our own

discretion)

Intellectual Property Rights of 3D Designs/Models/Prints

You, as a designer, retain ALL your intellectual property rights in your 3D design, including without limitation any and derivative works like 3D renders. Except for the rights and licenses specified below, 3DMSR

shall NOT use, modify, display or distribute your 3D design or derivatives thereof. By uploading your 3D design, you warrant that it is either your original creation and not copied from any third

party and/or entity or that you own the intellectual property rights of the design. You warrant that your User Generated Content will not infringe the intellectual property rights of third parties. Should your User. Generated Content nevertheless be found to be infringing and/or in violation of any law, you will defend 3DMSR against third party claims, and be held liable for all (direct and indirect) damages and costs incurred by 3DMSR with respect to such claims.

We retain the right to review and refuse any order when it, in our own discretion, appears to infringe third party intellectual property rights.

We are happy to sign non-disclosure/confidentiality agreements where necessary.

Consent to Use of Personal Data

By using our Services you agree that 3DMSR may collect and use personal data about you. Such information collected through this Website shall only be used for our own records and will never be sent, sold or distributed to any third parties without consent.

Limitation of Liability

These Terms and Conditions set out the full extent of our obligations and liabilities in respect of the 3DMSR Services. Save as set out below, there are no warranties, conditions or other terms that

are binding on us regarding the supply of Services except as expressly stated in these Terms and

Conditions. Any warranty, condition or other term arising out of or in connection with the Services or the delivered models which might otherwise be implied into or incorporated into these Terms and Conditions by statute, common law, laws applicable in the country where you ordered the Services or otherwise (including without limitation any implied term as to quality, fitness for purpose, reasonable care and skill) is hereby expressly excluded. 3DMSR WILL NOT BE LIABLE FOR ANY LOSS OF INCOME, LOSS OF PROFITS, LOSS OF CONTRACTS, LOSS OF DATA OR FOR ANY INDIRECT, INCIDENTAL, EXEMPLARY, SPECIAL, PUNITIVE OR CONSEQUENTIAL LOSS OR DAMAGE OF ANY KIND HOWSOEVER ARISING AND WHETHER CAUSED BY TORT (INCLUDING NEGLIGENCE), BREACH OF CONTRACT, WARRANTY OR OTHERWISE.OUR MAXIMUM AGGREGATE LIABILITY UNDER THESE TERMS AND CONDITIONS WHETHER IN TORT (INCLUDING NEGLIGENCE) OR OTHERWISE SHALL IN NO CIRCUMSTANCES EXCEED THE FEE RECEIVED FROM YOU BY 3DMSR FOR THE RELEVANT ORDER..

Indemnification

You agree to indemnify and hold 3DMSR, its partners, affiliates, distributors, dealers, agents

and its and their employees harmless from and against all liabilities, costs, damages and expenses

(including reasonable attorney’s fees) arising from or relating to any claims that result from your breach of

these Terms and Conditions.

Change of the Website, the Services and these Terms and Conditions

3DMSR reserves the right to make changes to the Website, the Services and these Terms and

Conditions at any time. Such amended Terms and Conditions shall be effective upon posting on this

Website and will have no effect on sales that were completed before such posting. We will make

reasonable efforts to post notices regarding any changes to these Terms and Conditions. Please check

the Terms and Conditions published on this Website regularly to ensure that you are aware of all terms

governing the Website and the Service.

Miscellaneous

These Terms and Conditions, together with the Privacy Statement and any other policies, guidelines, or

FAQs posted by 3DMSR represents the complete and exclusive agreement relating to the

subject matter hereof which supersedes any proposal or prior agreement, oral or written and any other

communications between you and 3DMSR. No amendment of these Terms and Conditions

shall be binding upon 3DMSR unless in writing and signed by 3DMSR. If any

provision is held to be void or unenforceable, such provision shall be reformed only to the extent

necessary to make it enforceable, and the invalidity or unenforceability of such provision shall not affect

the validity or enforceability of any other provision of these Terms and Conditions.

Contact Information

If you have any questions regarding these Terms and Conditions or the Services, you can contact us by sending an email to sales@3dmsr.com .

SHOULD YOU EXPERIENCE ANY PROBLEMS, PLEASE CONTACT US AND WE WILL DO OUR BEST TO FIX IT AS SOON AS POSSIBLE. SINCE WE ALWAYS WANT TO FURTHER IMPROVE OUR SERVICES, WE WELCOME ALL FEEDBACK. 3DMSR MAY CONTACT YOU TO ASK YOU ABOUT YOUR EXPERIENCES.

3DMSR